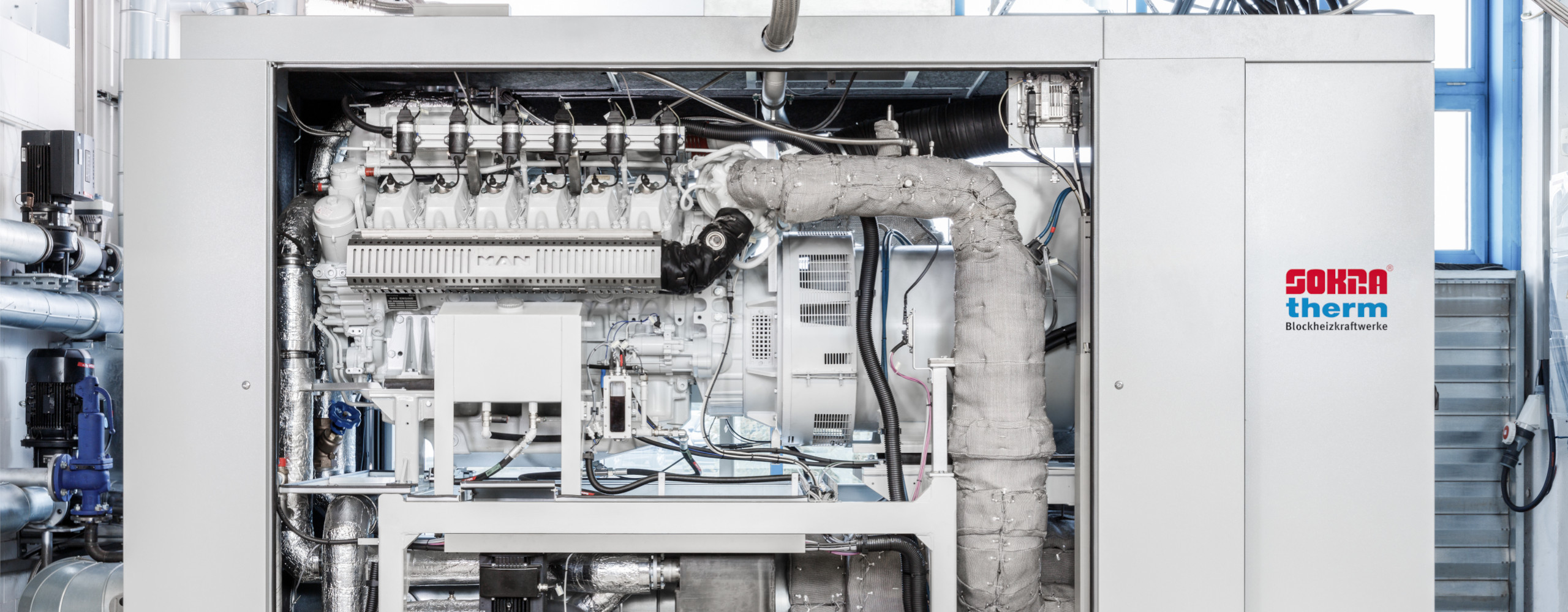

Die bei Stromerzeugungsanlagen anfallende Wärme nicht -beispielsweise über Kühltürme- abzuführen, sondern möglichst vollständig zu nutzen, ist die Kernidee der Kraft-Wärme-Kopplung (KWK). Unser Antrieb ist es, durch den Einsatz von kompakten Blockheizkraftwerken (BHKW) diese Idee so umzusetzen, dass sie möglichst viel Primärenergie einspart, die Umwelt von Schadstoffen entlastet und für den Betreiber eine wirtschaftliche und zukunftsfähige Versorgung mit Strom und Wärme sicherstellt.

Seit 45 Jahren überzeugen die von uns entwickelten BHKW-Kompaktmodule durch ihre:

Nicht zuletzt aufgrund dieser Kerneigenschaften haben wir seit Gründung unseres Unternehmens rund 2.000 BHKW-Kompaktmodule zur umweltschonenden Versorgung der unterschiedlichsten Objekte mit Strom und Wärme geliefert.